Creating a Gold Ring from Scrap

Function: Mother’s Day Gift

Inspiration: I wanted to find a way to use all this junk metal that I got from eBay, my mom, things around the house, etc.

Methods:

Phase 1: Separation

Melting down the scraps with nitric acid and welding the metal with copper

Phase 2: Recovery

Separating the gold from amalgam using nitric acid and concentrating the gold using chloroauric acid

Phase 3: Melting Gold and Forming Ingot

Melted gold in a kiln with a torch and formed ingot

Phase 4: Making the Ring Mould

Carved a positive of the ring out of wax and cast negative in plaster

Burned the plaster out and poured metal into the mould

Phase 5: Making the Ring

Let the metal cool in its mould

Remove by dissolving plaster with water

Sanded and polished

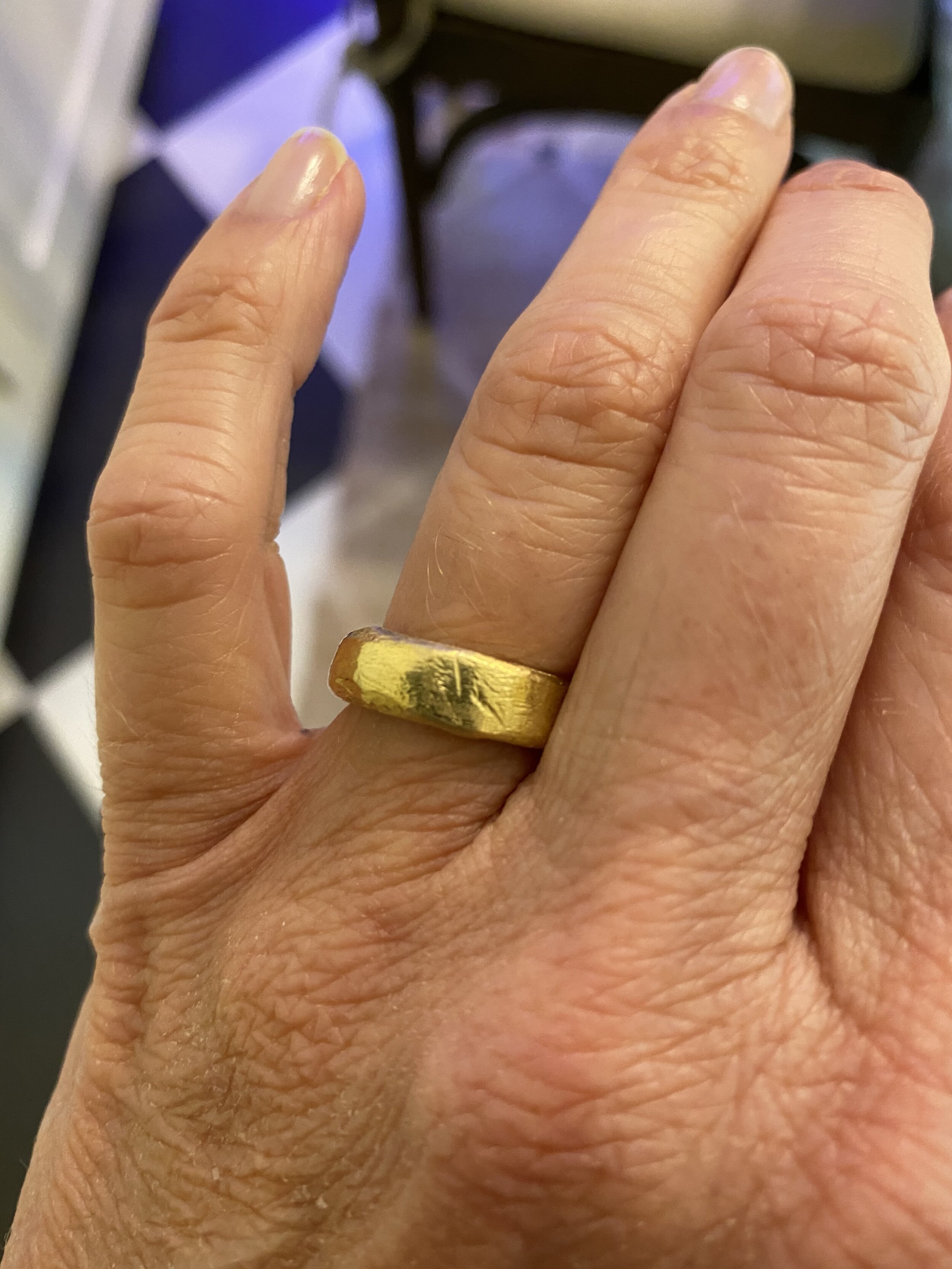

Outcome: Success, 12 grams of 24k (100%) gold; my mother was very happy with it. I wanted to polish it further but she preferred the “rustic” appearance.

Failures and Challenges:

I didn’t have enough gold for the first few attempts at pouring the ring and wound up with a ring band that was only 3/4 of a complete circle. When I finally had a successful pour and made a full band, I realized that I had forgotten to alloy the gold and ended up with a very soft, pliable ring. Not at all what I had planned. I then added some silver and copper to result in 22K gold and then poured another ring and finally had success.

Melted Gold and mixed with copper to form alloy

Forming a gold sponge out of the copper alloy

Thermal image of the production of chloroauric acid

Chloroauric Acid production

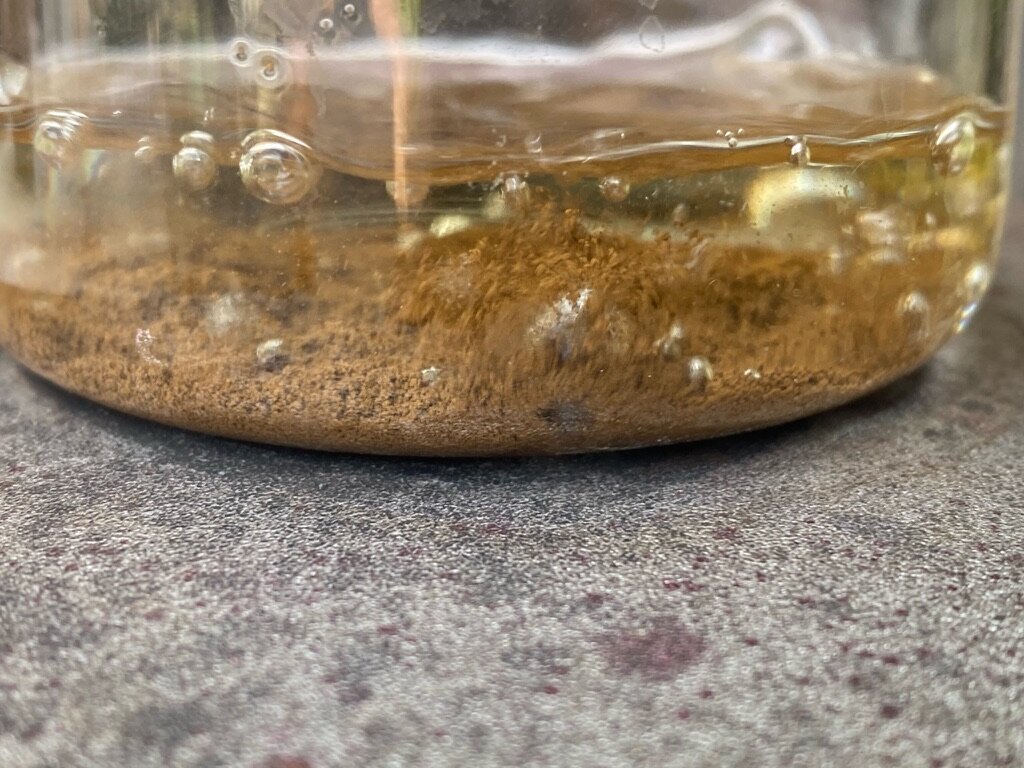

Very fine gold in solution

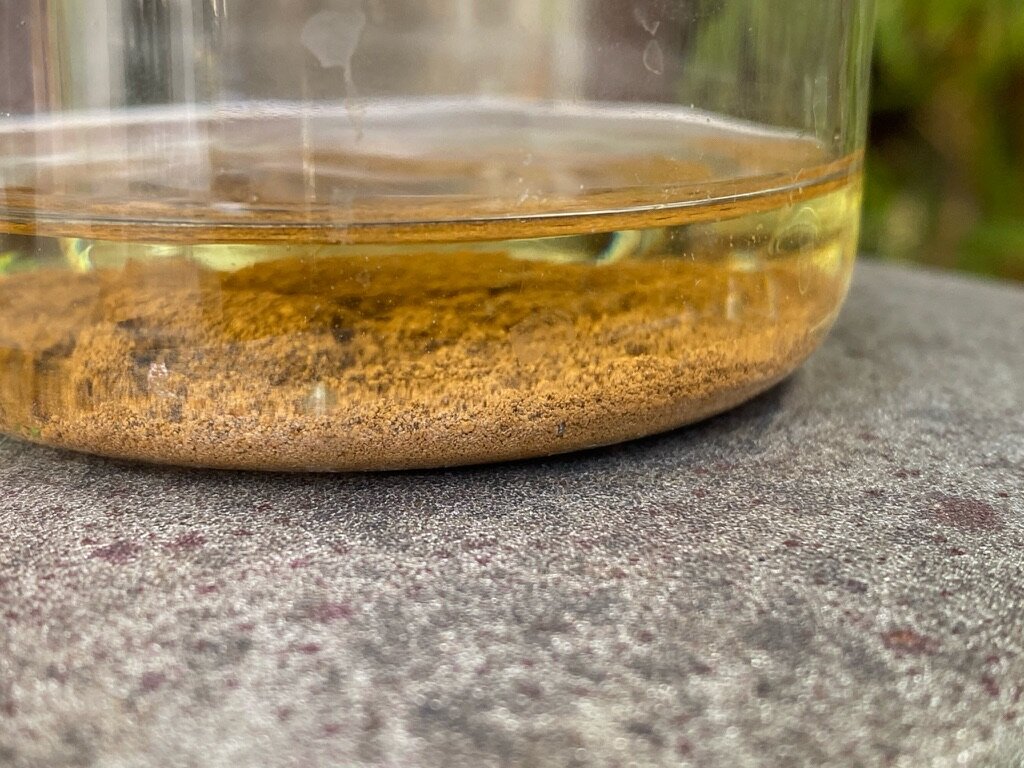

Gold powder in solution

Cleaning the Gold with HCI

Washing the cleaned Gold with boiling water

Dried and cleaned Gold powder

Melting the Wax out of the Mold

Melting down the final product to cast the ring

Mold with the gold ring inside

The finished Ring

Another angle of the finished ring

One of a few failed attempts at casting the ring.