3D Printer Build

Function: To design and create functional prototypes almost instantly.

Inspiration: I hoped it would be useful for prototyping, i.e. designing things and quickly iterating.

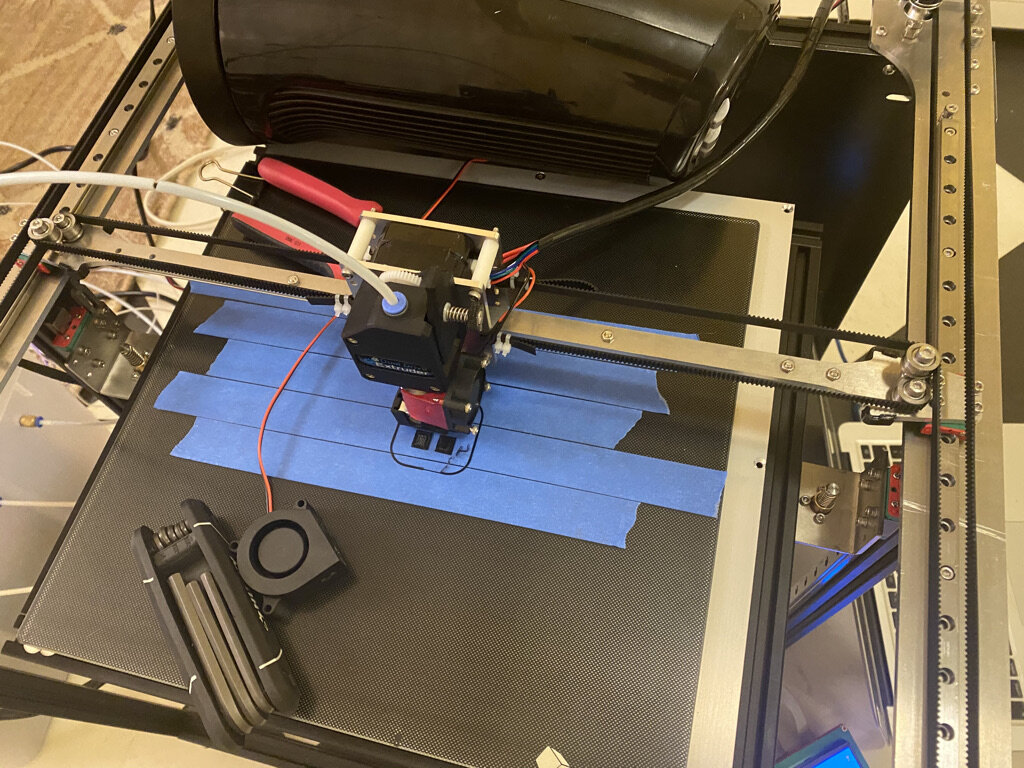

Methods: After reading papers on printing design and talking to friends who were also interested in 3D printing, I decided I wanted to build a CoreXY system—a new motion system for 3D printers. I sourced many parts from a vendor in Taiwan, and I also sourced parts myself. I spent approximately 35 to 40 hours on the initial printer, but a total of 60 hours tinkering and refining it.

Outcome: Extremely successful; I’ve been able to prototype and build/create various custom parts for my projects.

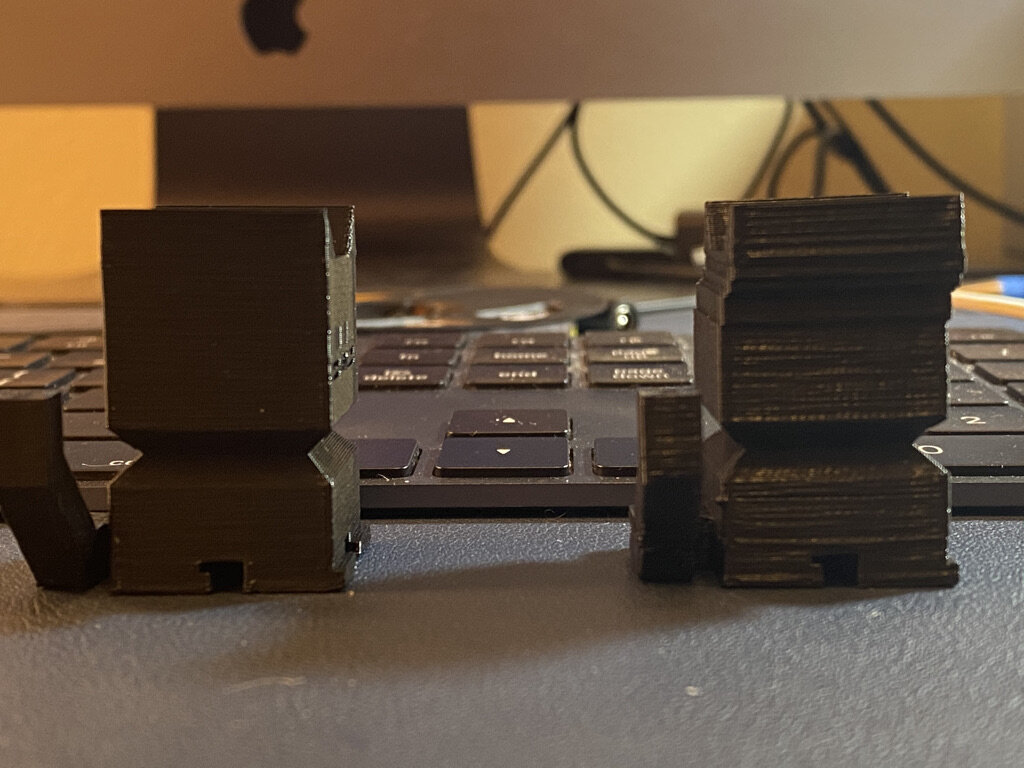

I also 3D printed a mount for a new piece I’m installing, which would hold the new hot end (i.e., the part that extrudes the filament) in place.

Built a web interface to access user’s printer from any computer, allowing users to connect their designs on Fusion 360 to the printer.

Failures and Challenges: no significant challenges with the build.

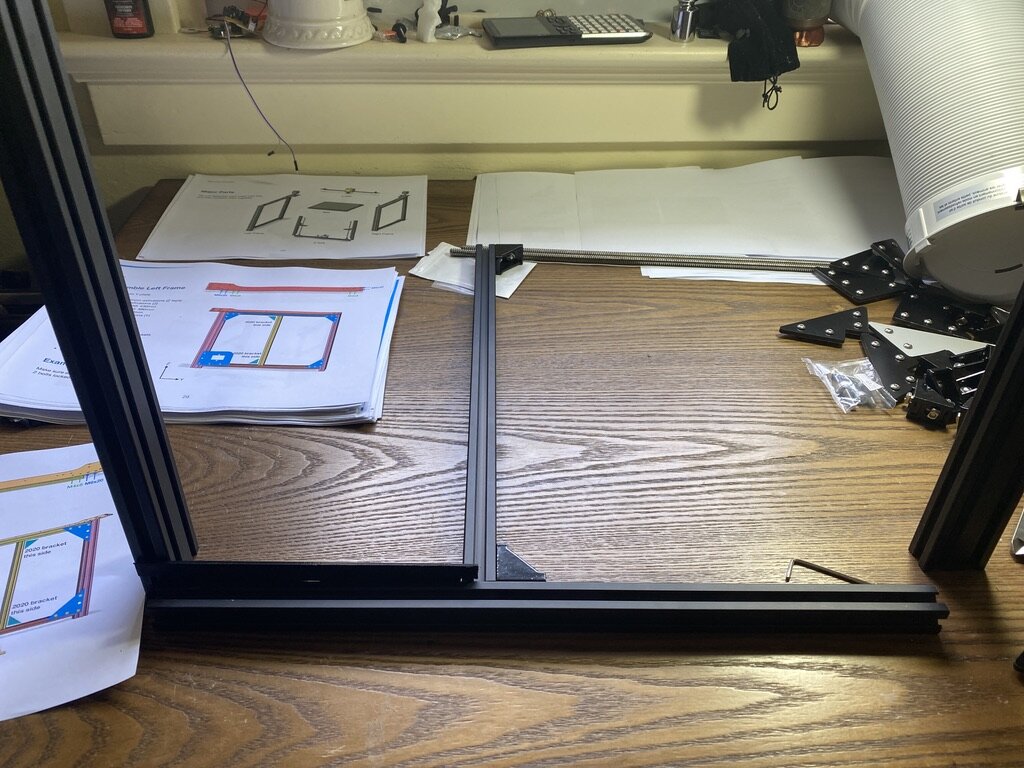

Squaring the Right frame

Squaring the Z axis

Left assembly

Frame assembled

The Skr Control board

First Test Print (It didn't go well)

Seccond test print

Test of the bed leveling probe

Testing a new glass bed

Right: First CaliCat. Left: Second CaliCat after some tuning

Old Hotend

Brand New Hotend!

First test print with new hotend at 500c!